Milling

CLAMPING

TOOLS

MILLING

OTHER SERVICES

See more on YOUTUBE canal Kastr CNC

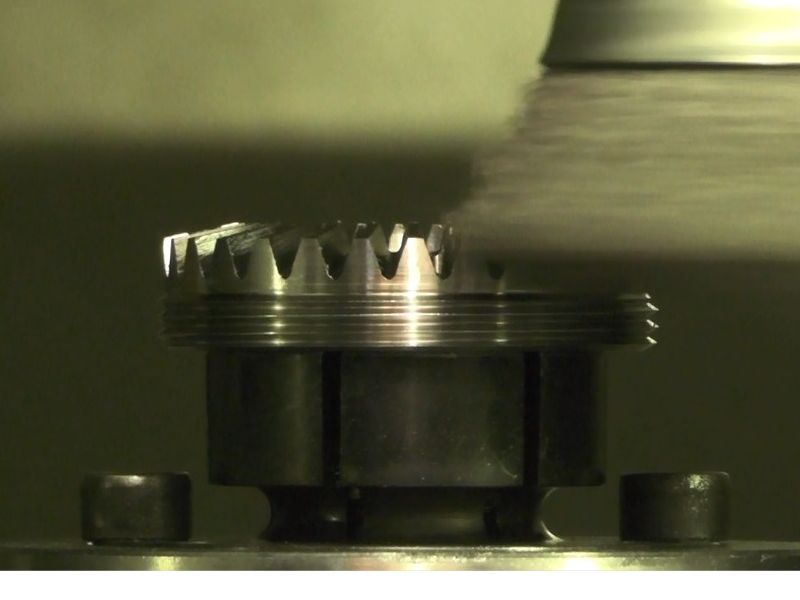

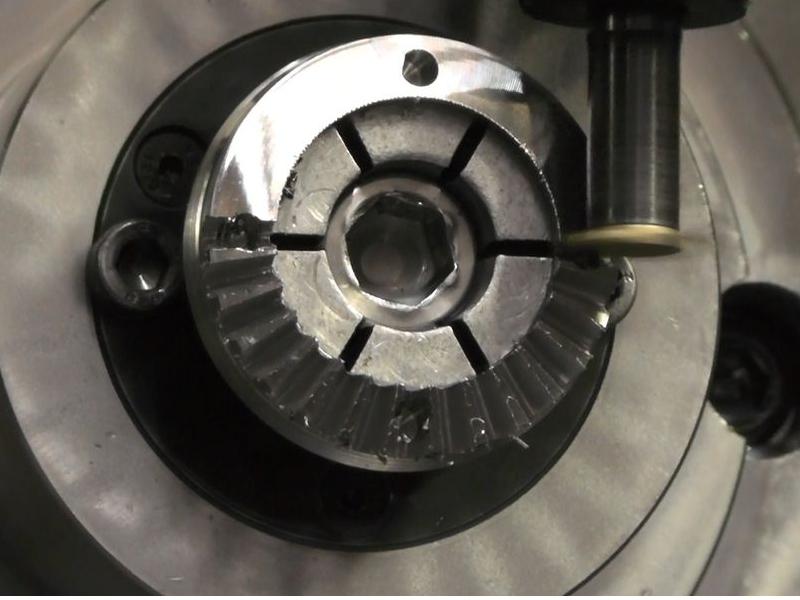

Cone gear milling with MULTI-MASTER tool

It is nothing new now that bevel gears can be milled in five axes without any problems. The only question is the productivity. Profiling with a milling cutter is definitely not a matter of one or two minutes. A limiting factor is also the tooth gear size. The smaller the gear teeth, the smaller tool must be used. With very small tools it only remains to run the milling head at high speed, while the productivity is far from being brilliant. The cone gears are, moreover, negatively affected with the fact that the tooth profile is narrowing in the direction to the gear center, and thus a too big tool is not capable of going over the critical point. As we have got in our hands production of cone gears with straight teeth, we have decided to do it in a different way – just by the above mentioned reasons. We have used the MULTI-MASTER tool by the ISCAR company. The head used has a shape of a hard metal saw, and as the teeth are straight, is is enough to only swivel the gear under the right angle so that it is possible to move tangentially to the involute tooth side. In principle only four axes are needed to do so. The service life of the MULTI-MASTER exchangeable heads is very good; that is why this principle proved convenient even for hardened material of the gears. Also the method of the cone gear automatic deburring is worth seeing.